Processing Capacity: 4-6Tons/hour

Application Scope: Fresh cassava peeling and washing

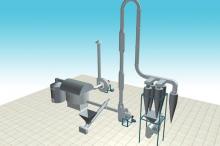

Product Introduction: Cassava processing machine, cassava washing machine, cassava cleaning machine, cassava peeling machine, cassava washing and peeling machine for cassava starch and flour processing

1. Solid and durable with all parts of the body including all food contact areas made of 304 stainless steel;

2. Operate safety with feed port outside the working area;

3. Continuous working with screw type feeding structure;

4. Adjust discharging speed to realize the best peeling effect with variable frequency motor;

5. Easy cleaning with all parts of the frame body made of 304 stainless steel;

6. With compact structure and beautiful appearance, very popular and acceptable in

cassava processing field.

Product Composition of Cassava Peeling and Washing Machine

1. Mainly consist of motor, transmission and the rotary brush, there are two kinds of brush: hard or soft one according to the materials being processed, the structure design can avoid over damaging of materials.

2. With two motors, one for driving the brush roller with rotary brush to remove the pieces of peel from the raw materials without any broken, another one for driving the central axis with counter vane to guide the peeled materials from the feed port to the discharge port, meanwhile along with water coming out of shower pipe and get the materials wet, make them easier for peeling and washing.

Technical Parameters of Cassava Peeling and Washing Machine

|

ModelNo.

|

GD-BP-2000

|

|

MachineMaterial

|

StainlessSteel

|

|

Capacity

|

4-6Tons/Hour

|

|

Voltage

|

380V/50Hz 3Phase

|

|

Power

|

3.0KW

|

|

RotateSpeed

|

160-500R/Min

|

|

The inner diameter of the rotary drum

|

800mm

|

|

The inner length of the rotary drum

|

2000mm

|

|

Weight

|

450KG

|

|

Dimension(L×W×H)

|

2850×1200×1120mm

|

EN

EN

fr

fr  es

es  it

it  pt

pt