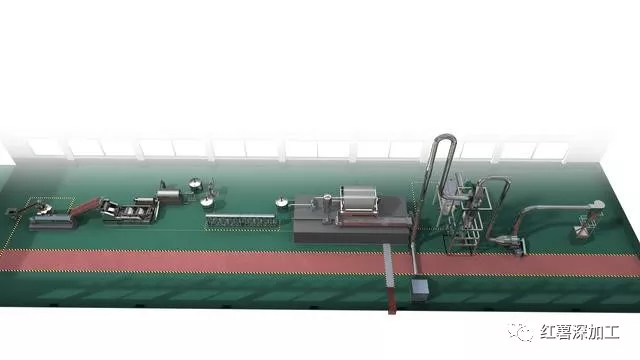

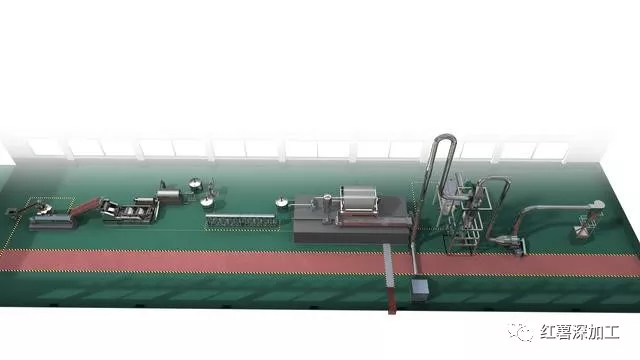

More and more powerful cassava starch processing factories begin to choose automatic cassava starch processing equipment. Some medium-sized processing factories are also considering phasing out the original cassava starch processing equipment, and then choose automatic cassava starch production line.

1. The high degree of automation

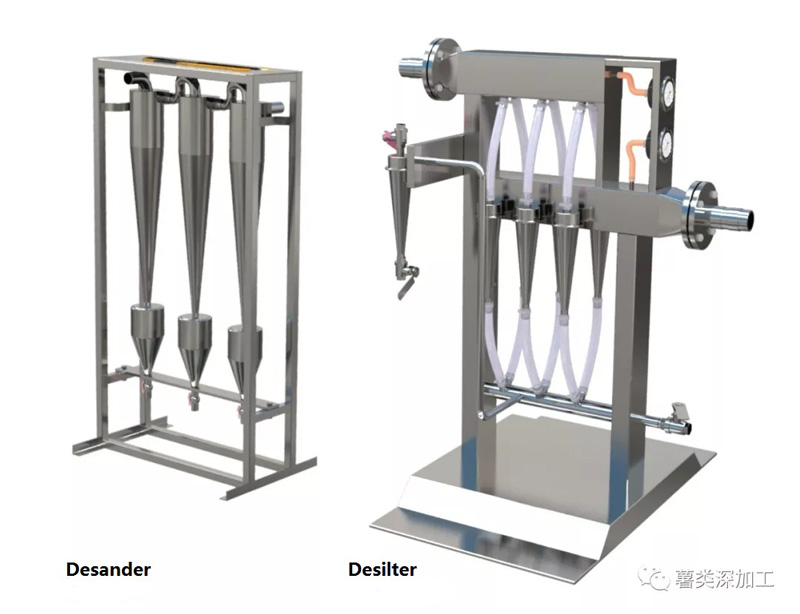

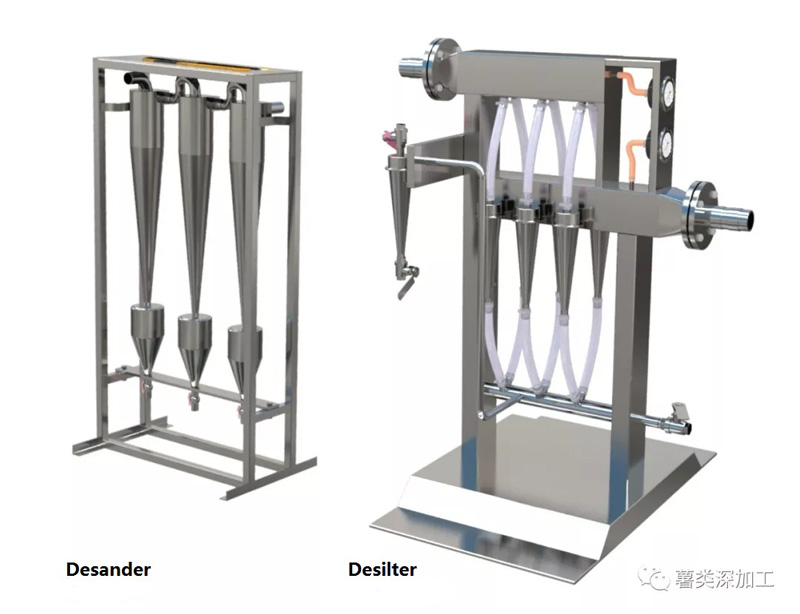

The automatic production line of cassava starch can realize the automation of cassava cleaning, crushing, extrusion, filtering, powder making, fine filtration, desilting and desilting, cyclone refining, dehydration and drying, automatic packaging and the whole process of cassava starch processing. In the case of higher and higher labor costs, in the long run, automation will undoubtedly greatly reduce production costs.

2. Good starch quality

The automatic cassava starch production line is equipped with four-stage cleaning and filtering equipment to ensure the delicate taste of starch.

Pulverizer in the flour-making stage integrates extrusion, filtration, and flour-making, and uses a cyclone to refine so that starch does not brown, and starch is white and delicate with good color.

In the production process of fully automatic cassava starch production line, most sections are operated by fully enclosed machines, and the materials of fully automatic cassava starch processing equipment are mostly stainless steel so that cassava starch will not be polluted by the external working environment and processing equipment in the production process.

3. Low Energy Consumption and Water Consumption

The crushing section of the fully automatic cassava starch production line adopts sorting crushing. Compared with traditional crushing, this operation can reduce energy consumption by more than 30%. The curved net extrusion pulverizer integrates crushing and filtering guarantees the continuity of starch production and saves the conveying section, which naturally reduces energy consumption.

The washing of curved-net extrusion pulverizer uses counter-current circulating water, which can save 40% of water. At the same time, extrusion filtration + pressureless infiltration can further reduce energy consumption and water consumption.

4. Simple installation and convenient maintenance

The automatic cassava starch production line is easy to install, disassemble and maintain.

5. Seiko equipment, reliable operation, and high efficiency

Large manufacturers of automatic cassava starch processing equipment, scientific and rational design, precision forging, the long service life of finished equipment. The structure and technology of the automatic cassava starch processing equipment are scientific and reasonable, and the daily processing capacity of the automatic cassava starch processing equipment is also large.

That is to say, the above five advantages make more and more large manufacturers choose automatic cassava starch processing equipment.

EN

EN

fr

fr  es

es  it

it  pt

pt