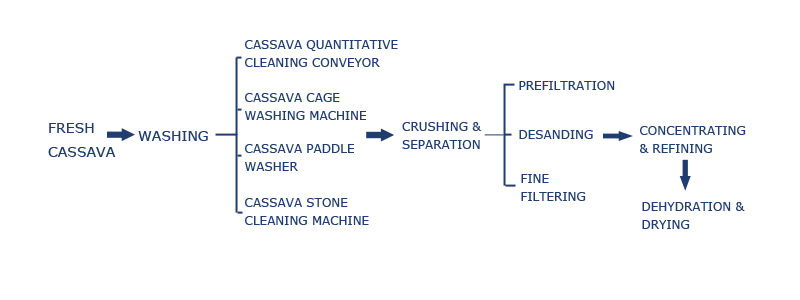

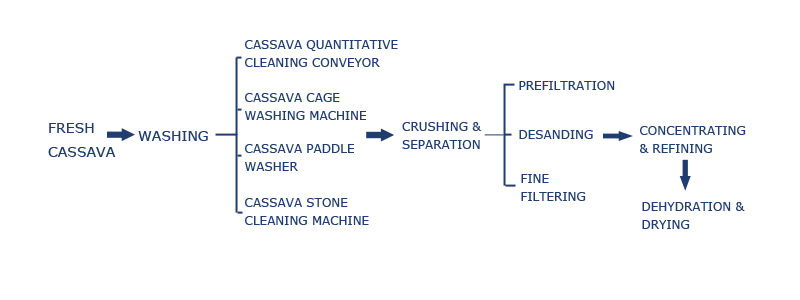

1.Process

2.Production capacity

Small-scale processing: 1.5-2 tons / hour, 3-4 tons / hour

Medium-scale processing: 5-6 tons / hour, 6-8 tons / hour, 8-10 tons / hour

Large-scale processing: 15-30 tons / hour

The above processing amounts are based on the amount of processed fresh potatoes per hour. If the production volume of 7, 12, 20, 30, 50 tons of production is produced by the amount of starch production, it is generally an automated production line that directly produces dried starch. Among them, less than 12 tons is small-scale processing, and more than 50 tons is for large-scale processing.

3. Applicable objects

It is mainly used in sweet potato starch, potato (potato) starch, tapioca starch, arrowroot starch, cannabis starch, lotus root starch and the like.

4. Floor area

Tip: For simple processing, it includes a circulation pool, an operation channel, a device footprint, and a console. However, the area of the starch precipitation tank is not counted. The starch precipitation tank can be calculated according to the processing volume. Generally, the water per ton of raw materials is 2-3 cubic meters, and the sedimentation tank covers 1.8-2.5 square meters. It can be calculated according to the daily processing time. Also pay attention to the volume and area of the tank used for wet starch storage.

For automated production lines, the land occupation will vary according to the configuration of the production line, but the overall production line below 20 tons covers an area of 300-500 square meters, and more than 30 tons is generally more than 600 square meters.

5. Main equipment

Wet starch processing:

cassava washing machine,

crusher,

filtration equipment (cesh crusher, overflow elutriation crusher), sand remover, desilter, fine filter, starch microfiltration machine.

The processing of refined starch needs to be selected:

starch swirling station, starch vacuum dehydrator, starch airflow dryer.

6. Equipment features

(1)Advanced technology, beautiful appearance and compact layout;

(2)Small footprint, low employment, low labor intensity and high degree of automation.

(3)Low energy consumption, water saving, power saving, and low processing cost;

(4)High starch extraction rate and good starch whiteness.

(5)The quality of starch is high, reaching the national food grade standard;

(6)Multi-functional, applicable to: starch production of potato, sweet potato, banana, cassava, puerarin, lotus root, etc.;

(7)Stable performance, easy operation and maintenance

7. Auxiliary facilities

(1)Transformers and distribution cabinets, water supply systems.

(2)Corresponding warehouses and stacking sites, micronized collection tanks, transfer tanks or transfer tanks. Welcome to inquire detailed parameters, configuration and price.

8. Points to explain

(1)The above groups of equipment are all

cassava deep processing machinery. After processing the starch into raw materials, the potato can be packaged and sold, and the starch can be stored for processing the three powders (starch, vermicelli, and powder) to obtain higher profits.

(2)Users who do not need to process the three powders can dry or sell the starch.

(3)The above groups of equipment are all automated production lines, and only need to put the raw materials into the

cassava washing machine to automatically complete the production.

EN

EN

fr

fr  es

es  it

it  pt

pt