About the purchase of starch processing equipment is not a simple matter. For most users, starch processing usually starts with raw material cultivation (sweet potato, potato, pueraria, cannabis, etc.). It took about half a year from seedling sowing, field management, and harvesting. During this period, it is necessary to start a market inspection and purchase equipment. In addition to some small family-sized processing users, the emerging large and medium-sized starch processing enterprises have to start site selection and plant planning in advance, planning and layout and other more time-consuming things.

In order to put into production as soon as possible, and to join the season of

cassava starch processing, it is recommended that users arrange for mastery of the starch processing plant construction schedule, raw material harvest time and other subjective factors. It is best to order equipment in time (advance) in June-August. Considering that the custom starch processing equipment has a long production cycle, orders for a large number of starch and vermicelli processing equipment may cause delays in delivery time. Coupled with equipment delivery, installation and commissioning, production testing and other stages of work, will affect the user's starch processing and production.

In order to make effective use of valuable time for each user, make the right choice before the production and processing season, specially sort out this article to help users understand how to choose starch processing equipment!

1. The main parameters of the equipment

(1) Productivity

The productivity of equipment is generally expressed in terms of product output per unit time (hour, day, year). For example, for simple processing, it is calculated based on the output of raw materials; and the automated production line is calculated based on the output of dry starch.

Equipment productivity should be adapted to the actual needs of the user's company, company, individual, plant planning, production plan, planting volume, acquisition volume, and raw material supply. You can't blindly ask for the higher the productivity, the better, otherwise the raw material supply can't keep up, and the production is not balanced. Not only can not play the full effect but cause losses. Because of the high productivity of equipment, the degree of automation is generally high, investment is large, and energy consumption is large. If you can't achieve the output of your own design, the average cost of the product will increase.

(2) Processability

One of the most basic requirements for machine equipment is to meet the technical requirements of the product process. Our ability to meet the requirements of the production process is called processability. For example, a low-volume production line will have a small initial investment, but the cost of running will increase. The highly automated production line is just the opposite. In addition to the above basic requirements, the requirements for equipment operation control are also important. Generally, the equipment is required to be simple to operate, saving time and effort. Equipment with a large output requires a high degree of automation.

2. Equipment reliability and maintainability

(1) Reliability of equipment

Reliability is a prerequisite for maintaining and increasing equipment productivity. People investing in equipment purchases hope that the equipment can operate without problems in order to achieve the intended purpose. This is the reliability of the equipment.

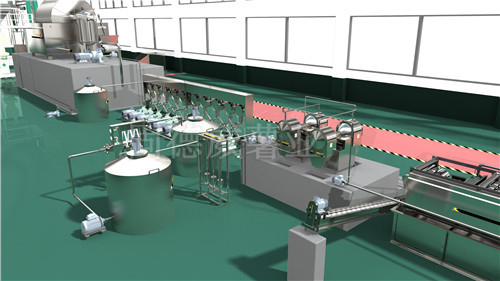

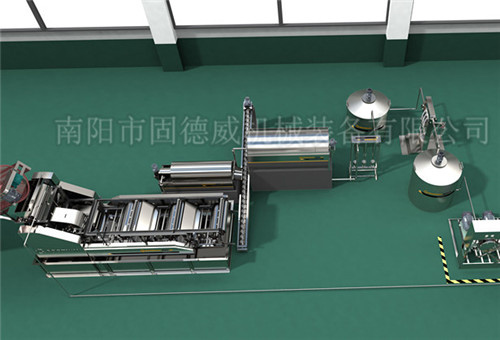

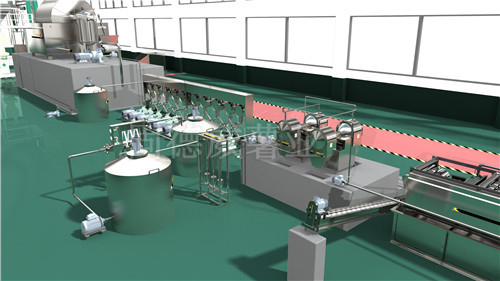

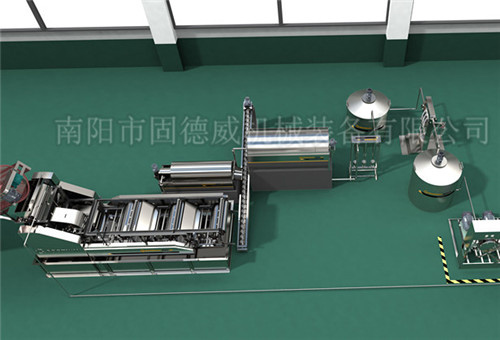

Reliability depends to a large extent on the design and manufacture of the equipment. Therefore, in the selection of equipment must consider the design and manufacturing quality of the equipment, try to choose a professional manufacturer. Why choose a professional manufacturing company? Every piece of equipment produced by a professional manufacturer is put into the market after passing through the inspection and strict examination by the professional technicians of the manufacturer. Every device designed is reasonable in terms of design principles, process flow and so on. Since 1991, Goodway Potato Machinery Factory of Nanyang City, Henan Province has been focusing on the research of starch equipment. The only overflowing pan-washing

cassava starch processing machine and the stencil extrusion cassava starch processing machine that have obtained the national patent and the only ones that have been included in the national financial subsidy, have a big improvement in comparison with similar products in terms of energy consumption, water consumption and power consumption.

(2) Maintainability of equipment

Similarly, once the purchased equipment fails, it must be repaired in a timely and convenient manner. That is, the maintainability of the equipment is better. When selecting a device, the maintainability of the device can be measured in the following ways.

1 The technical drawings and materials of the equipment are complete. It is convenient for maintenance personnel to understand the structure of the equipment, easy to disassemble and inspect.

2 The structure design is reasonable. The overall layout of the equipment structure should conform to the principle of accessibility, and the parts and structures should be easily accessible for inspection and maintenance.

3 The simplicity of the structure. Under the premise of meeting the requirements of use, the structural requirements of the equipment should be simple. The smaller the number of parts to be repaired, the easier it is to disassemble and the quick replacement of consumables.

4 The principles of standardization and combination. Equipment uses standard components and components whenever possible. It can be easily disassembled into several separate components, devices and components, and can be assembled into a complete machine without special means.

In addition, we must have a good after-sales service quality. Maintenance technical requirements are as close as possible to the area of the equipment.

3. Equipment safety and operability

(1) Equipment safety

Safety is the guarantee of equipment safety for production. That is, the equipment should have the necessary safety protection design and equipment to avoid human, machine accidents and economic losses.

(2) Operational equipment

The operability of the equipment is in the ergonomics category. The overall requirements are convenient, reliable, safe and ergonomic.

4. Environmental protection and energy saving of equipment

The environmental protection of equipment in industries such as industry, transportation, and construction usually refers to the degree of influence of noise vibration and harmful substances on the surrounding environment. In the selection of equipment, noise, vibration frequency and harmful emissions must be required to be controlled within the limits of national and regional standards.

The energy consumption of a device refers to its primary or secondary energy consumption. It is usually expressed in terms of the amount of energy consumed by the unit's operating time. In the chemical, metallurgical and transportation industries, energy consumption per unit of production is also used to evaluate the energy consumption of equipment. At the time of selection, no matter which type of enterprise, the equipment purchased must comply with the standards set by the National Energy Conservation Law.

5. Equipment economy

The economics of equipment selection are broadly defined. Each enterprise can select and analyze the main factors affecting the economics of the equipment according to its own operating characteristics and production and processing needs.

The economic factors that should be considered when selecting equipment are: 1. Initial investment; 2. Adaptability to products; 3. Production efficiency; 4. Durability; 5. Energy and raw material consumption; 6. Maintenance and repair costs.

The initial investment of equipment mainly refers to the purchase cost, transportation cost, installation cost, and auxiliary facilities cost. When purchasing equipment, it is not easy to seek evaluation criteria that are cheap and reduce other influencing factors. The equipment developed by Goodway Potato Industry Machinery Factory in Nanyang City, Henan Province can meet the different needs of different levels and different users. The equipment price is low and the quality is guaranteed.

The so-called equipment selection is from a variety of equipment of different models and specifications that can meet the same needs. After technical and economic analysis and evaluation, choose the best solution to make purchasing decisions. Reasonable choice of equipment allows the limited funds to maximize economic benefits.

EN

EN

fr

fr  es

es  it

it  pt

pt