Processing Capacity: 3-20Tons/hour

Application Scope: Fresh cassava washing to remove surface mud and sand

Product Introduction:

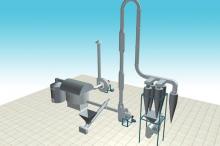

Cassava processing machine, cassava washing machine, cassava cleaning machine, cassava peeling machine, cassava washing and peeling machine for cassava starch and flour processing

Product Description of Cassava Paddle Washer

1. Interior structure: there are multiple mixing blades connected to the central axis, and the direction and angle of the mixing blades can be adjusted manually according to the practical needs.

2. U-shaped Tray: used to support the screw axis is also a container of water, raw materials operation in the central axis, driven by U-shaped groove at both ends of the feed inlet and discharge port and the next process the mouth is connected to the necessary iron to connect or seal; feed inlet is open, for receiving materials to enter.

Drive: drive the functioning of the central axis.

3. Working Principle: base on bionics principles and integrate of mixing, friction, rubbing, upthrowing and impacting to remove all the impurity in the insect hole forcefully, such as the silt, sand, stone, iron etc without any broken of the raw material, to achieve a perfect washing effect.

Technical Parameters of Cassava Paddle Washer

|

ModelNo.

|

MachineMaterial

|

OverallSize(L×W×H)

|

Weight

|

Power

|

Capacity

|

|

GD-JY-350

|

Stainless/Carbon steel

|

4600×850×900cm

|

400kg

|

3.0kw

|

3-20tons/hour

|

EN

EN

fr

fr  es

es  it

it  pt

pt