Processing Capacity: 100-300kgs/hour

Application Scope: Garri frying or roasting

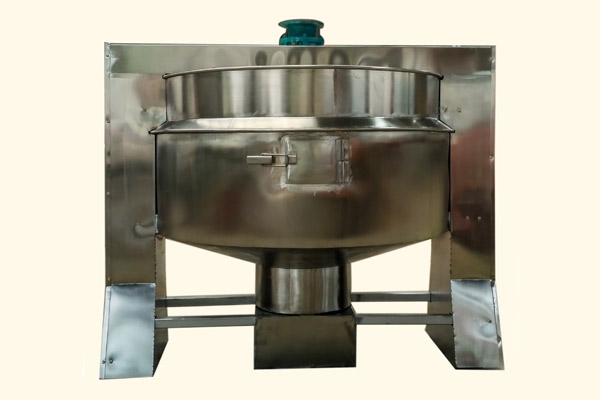

Product Introduction: Garri processing machine, including garri fryer, cassava fryer machine, cassava frying machine, cassava roasting machine, and cassava drying machine, designed for efficient cassava garri processing.

1. This type of

garri fryer is a stirring pot, and the heating method can be electric/gas;

2. It adopts the "Scraping Bottom Type" mixing and stirring, making the materials mixing more evenly and fully without the dead angle. With heat conduction oil as the medium, so it is non-stick between materials and fryer;

3. Two independent heating controlling systems, make heating temperature be regulated, and automatically controlled;

4. Without the danger of open flame, explosion, and fire;

5. Simple installation and easy operation.

6. Hand wheel-shaking discharging. It is efficient and practical.

Roasting is done mechanically using an automated Garri fryer made of stainless steel material and with electricity, natural gas, firewood or charcoal as the heat source. The finished product (Garri) is usually recognized from the color change from white to cream (for non-palm oil fortified Garri) and crispy hand feel of the grains/particles.

Product Structure of Garri Fryer Machine

1. Pot: The fryer has a flat pot with stainless steel material, with few overall roundness errors, with a pot stirrer affixing high, avoid the paste pot phenomenon.

2. Heating system: Using a variety of heat in the form of coal, electric, gas and other options available to customers.

① Electric: A large heated area, temperature-controlled, heat evenly.

② Gas: Easy to use, fast heating, meet some of the demand for high temperature, unrestricted factory voltage.

③ Coal: Original heat source used for local traditional garri processing.

3. Mixing system: mixing method using a special tilt rotation, so that the planet is stirrer and pot full contact, the implementation does not rotate with the autobiography of rotation integer ratio, so that the pot without stirring dead, more uniform material mixing, scraping the bottom more thorough, not prone to paste pot phenomenon.

4. Speed gear: the use of advanced under stirring shaft drive and seal structure, so the pot clean and sanitary; speed frequency control power, smooth operation.

All parts of the frame body and all food contact areas are 304 stainless steel and polished, consistent with "People's Republic of China Food Sanitation Law" requirements, with beautiful appearance, reasonable design, compact structure, easy installation, simple operation, easy maintenance.

Technical Parameters of Garri Fryer Machine

|

Model no.

|

GD-EF-1200

(Electric heating)

|

GD-GF-1200

(Gas heating)

|

|

Machine material

|

Stainless steel

|

Stainless steel

|

|

Capacity

|

150-200KG/H

|

150-200KG/H

|

|

Power

|

18KW

|

1.5KW

|

|

Voltage

|

380V/50Hz 3Phase

|

380V/50Hz 3Phase

|

|

Rotate speed

|

29R/Min

|

29R/Min

|

|

Heat transfer area

|

2m2

|

2m2

|

|

Operating temperature

|

150-180℃

|

150-180℃

|

|

The inner diameter of the pot

|

1200mm

|

1200mm

|

|

Inner depth of the pot

|

400mm

|

400mm

|

|

The inner volume of pot

|

400L

|

400L

|

|

Weight

|

750KG

|

750KG

|

|

Dimension(L×W×H)(mm)

|

1500×1500×1250

|

1660×1400×1200

|

EN

EN

fr

fr  es

es  it

it  pt

pt