Features

Related Products

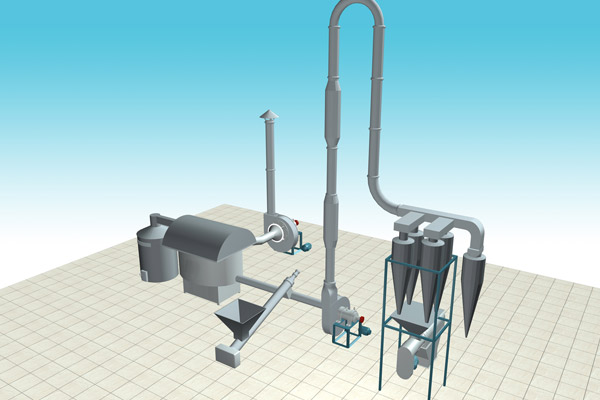

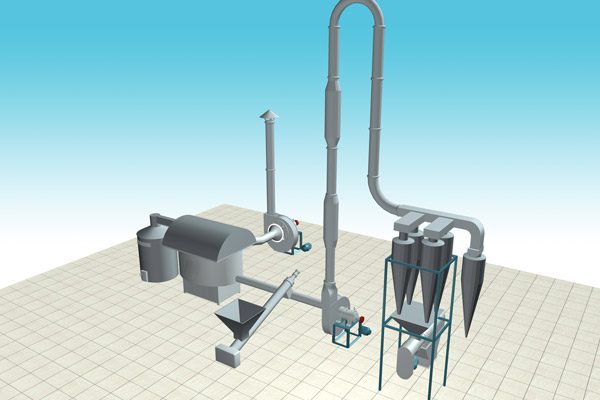

Features of Cassava Drying Machine

Processing Capacity: 100-2000Kgs/hour

Application Scope: Cassava starch and flour drying

Product Introduction: Airflow flash dryer, cassava starch drying machine, cassava flour drying machine for cassava starch and flour processing

1. Hot air sucked in along with wet starch(less than 40% moisture content) fed in;

2. Digital Control to make sure the powder cannot be burnt;

3. Flash speed powder go through the drying tower, higher than 10 meters;

4. Dry powder collected from the collector, but tailings are collected by another end to make sure completely collection;

5. Starch powder needs to be screened again to make sure no leaves or other things got in;

6. Connected with automatic weighing and packaging machine;

7. Aluminum or Stainless Steel can be selected;

8. 24 Hours Continuous work available;

9. Moisture content less than 13% for the ready-to-pack powders;

10. Heat resource can be built by yourself or use a steam boiler;

11. We do not offer bags for packaging, the weighing scope is 5KG-50KG adjustable.

The cassava starch factory at present normally adopt airflow drying (also called flash drying), the whole process time is completed in an instant, so the internal moisture of the starch granules have been dry before gelatinization, the pasting or degradation phenomenon will not occur. Airflow drying is concurrent flow drying process, namely, the concurrent flow of wet powder material and the heat flow, consists of heat transfer and mass transfer process. When wet starch with the hot air in contact, hot air transfer heat to the surface of the wet starch, again from surface to interior, the process is the heat transfer process; At the same time, the moisture in wet starch diffusion from the material inside to the surface of starch by liquid or gaseous, and then diffusion into the hot air from the starch surface through the gas film, it is a mass transfer process. By the high-temperature air and wet starch balanced heat exchanging in the drying tube, the drying starch become dry powder, and then packing and warehousing after cooling.

Product Application of Airflow Flash Dryer

Widely used for the drying in starch, modified starch, medicine, food, chemical industry etc particle materials.

Technical Parameters of Airflow Flash Dryer

|

Model number

|

Output yield

|

Power

|

Voltage

|

Final water content

|

Material

|

Cover area

|

|

GD-HG-300

|

300kg/hour

|

13kw

|

380V/50Hz

|

≤13%

|

Stainless steel

|

30-40m2

|

|

GD-HG-500

|

500kg/hour

|

22kw

|

380V/50Hz

|

≤13%

|

Stainless steel

|

30-40m2

|

|

GD-HG-1000

|

1000kg/hour

|

30kw

|

380V/50Hz

|

≤13%

|

Stainless steel

|

40-50m2

|

|

GD-HG-2000

|

2tons/hour

|

60kw

|

380V/50Hz

|

≤13%

|

Stainless steel

|

70-80m2

|

Related Products Cassava Drying Machine

-

During the production process of fresh cassava, the crushing section is very important for the quality of final products, the cassava crusher machine for starch processing can crush the washed cassava...

-

During the production process of cassava starch, the sieving section is used to separate the fine residues(fiber) from the cassava slurry, remove the residues, reserve and convey the cassava slurry to...

-

The section of cassava washing machine is designed as the first steps of cassava starch processing, cassava flour processing and garri processing, so it is very important for the fresh cassava process...

-

The section of dewatering and drying has come to final steps of cassava processing, the vacuum dehydrator can remove as much moisture as possible and the flash dryer can dry the wet starch to low mois...

-

Cassava Washing Machine - Cassava Peeling and Washing MachineProcessing Capacity: 4-6Tons/hourApplication Scope: Fresh cassava peeling and washingProduct Introduction: Cassava processing machine, cass...

-

Cassava Crusher - Cassava Grater MachineProcessing Capacity: 3-6Tons/hourApplication Scope: Grating the cassava into slurryProduct Introduction: Cassava grater machine, cassava grating machine, cassav...

-

Cassava Chips Making Machine - Make Cassava Chips from Fresh Cassava

-

Dewatering and Drying System - Garri Fryer MachineProcessing Capacity: 100-300kgs/hourApplication Scope: Garri frying or roastingProduct Introduction: Garri fryer, cassava fryer machine, cassava fryin...

EN

EN

fr

fr  es

es  it

it  pt

pt