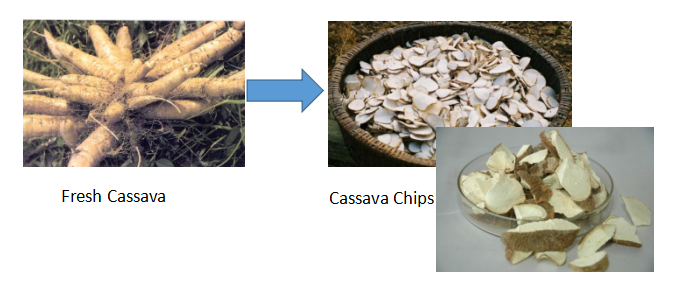

Cleaning and Washing Cassava Roots

Wash the fresh cassava roots in clean water to remove the surface mud and sand. It's the first step of cassava chips process and very important for the quality of final cassava chips.

- Home

- About Us

-

Products

- Cassava Crusher

- Cassava Sieving Machine

- Cassava Washing Machine

- Dewatering and Drying System

- Cassava Peeling Machine

- Cassava Grinding Machine

- Cassava Chips Cutting Machine

- Cassava Drying Machine

- Cassava Garri Fryer

- Potato Washing Machine

- Cassava Flour Milling Machine

- Cassava Harvesting Machine

- Cassava Starch Extraction Machine

- Case

- News

- Service & Parts

- Contact Us

EN

EN

fr

fr  es

es  it

it  pt

pt