The impurities in starch and starch products mainly refer to the sediment, crude fiber, protein and the like contained in the inside. The high content of impurities in starch will affect the quality of fans, vermicelli and powder products during subsequent processing. Not only the color is poor, the grade is low, and the taste is even worse.

Among them, the crude fiber content is too much, the powder strip is easy to break, and the color is poor. The protein content is high, and the strength of the noodles is increased, which has a certain influence on the fermentation industry, and has a great influence on the color of starch and starch products. The silt content is high, and the processed vermicelli noodles do not meet the food hygiene standards. There is a feeling of gums when chewing, which can cause aversion to its food. There are several reasons for excessive impurities in starch and products:

1. Raw material cleaning is not thorough

The sediment in the raw material is the main source of sediment in the starch. The reason for the excessive adhesion of raw materials to the sediment is mainly due to the lack of strict cleaning process and insufficient cleaning. The amount of sediment entering the starch is increased.

① When the roots or tubers of potato roots are harvested, the soil is too wet and sticky, and the surface of the potato is much muddy. When the wet mud is not dry, it is cleaned and processed, which is difficult to clean and has a large residual amount after washing. When using sweet potato, cassava potato, etc. as the raw material of starch, the screening of the clods and sands contained in the raw materials is not strict, and some impurities enter the grinding system.

② The raw materials are not thoroughly cleaned, not serious, and the water consumption is small. The processing of sweet potato starch is mostly manual and semi-mechanized processing, and the cleaning process is mostly manual cleaning. During the cleaning, some lack the soaking process. Direct cleaning is difficult to clean in a short time. Some use less water and are not cleaned after the initial cleaning, still with a certain amount of sediment. Some of them only pour a few times with water on the potato heap or rush with a tap, and they begin to grind. What's more, the surface of the potato skin seems to be relatively clean, and it is ground without washing. A large amount of pollutants and impurities such as sediment and residual soil enter the follow-up section, making it more difficult to clean up and endangering human health.

2. The container used for standing sedimentation and the method of stirring are improper

(this method refers to, the processing method of homemade sedimentation tank or the processing mode of hand workshop in the production line of simple sweet potato starch processing equipment)

In the case of sedimentation, it is generally preferred to use a container having a slightly concave center at the bottom of the circle, such as a large cylinder, a yellow barrel, a round pool, and the like. If you choose a square pool, it is not convenient to collect sediment at the bottom. If the starch is all stirred up while stirring, it is continuously stirred in one direction to form a vortex in the middle of the slurry. This is conducive to concentrated sedimentation and collection of sediment. However, after disorderly stirring or stirring, a vortex cannot be formed in the center of the slurry in the container, which causes the sediment to be disordered. Excessive mixing in the starch layer is not conducive to separation.

3. The mesh is large and lacks the second filtration.

When the pulp is separated, some manufacturers use only about 60 mesh, which causes a lot of fine slag (coarse fiber) to leak into the sieve together with the starch milk. The same coarse screen was used for the second precipitation, or there was no secondary filtration at all. This makes the fine slag easy to mix with yellow powder and small granular starch. This causes an increase in the amount of impurities such as coarse fibers in the starch. It is possible to use about 80 mesh for the first separation and about 120 mesh for the second separation.

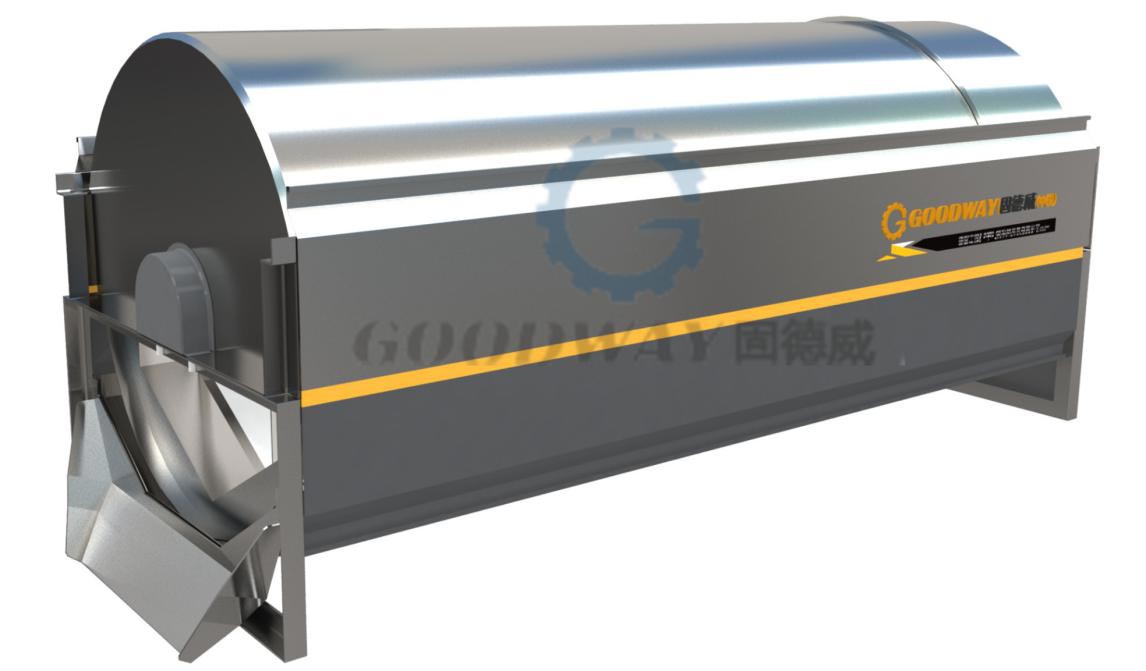

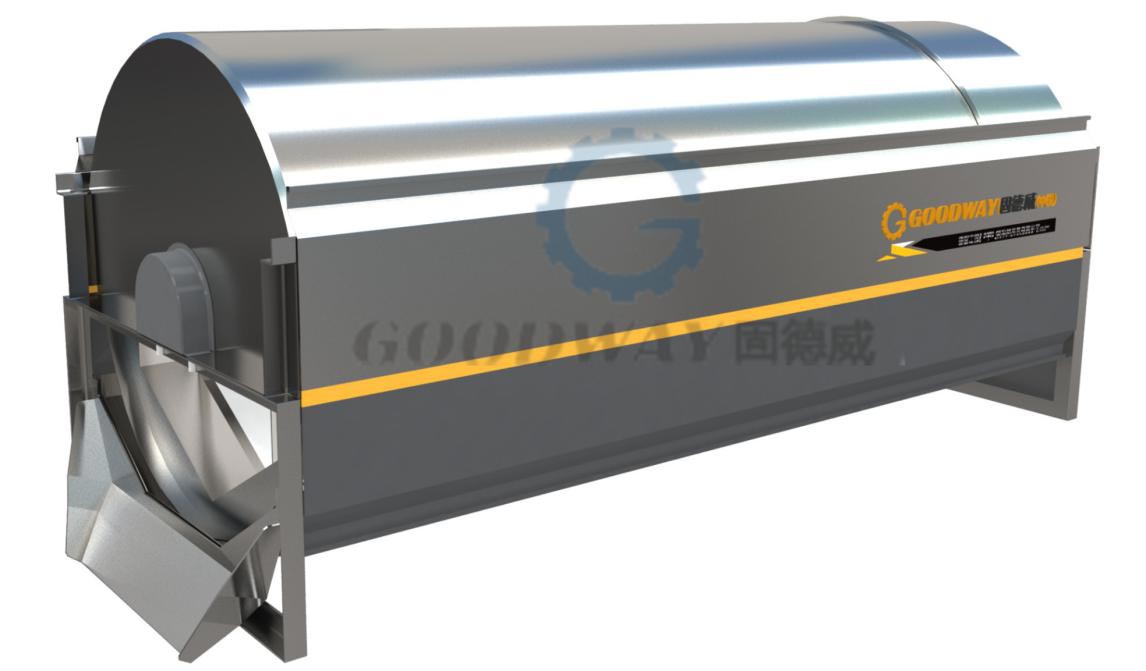

Goodway's filtration equipment - fine filter - has 2 fine filters, 120-140 mesh screen. It is specially designed for the extraction of high-purity white starch and also for the filtration of crude starch.

Microfiltration machine----160-260 mesh screen, ultra low speed rotation. It removes fine impurities from starch and fully guarantees the fineness of filtration.

4. Protein separation is not thorough

① Acid slurry method: When the acidity of the acid slurry reaches the isoelectric point of the protein, the protein adduct precipitates between the small granular starch in the upper layer of the starch, which causes difficulty in separation.

②Automated machinery (starch cyclone station): When using a cyclone to separate proteins, some mechanical properties are poor or inaccurate, so that protein is mixed into the starch slurry into the dehydration system.

5. Operation is not standardized

Excessive starch impurities caused by improper operation are mainly manifested in the following aspects:

1 When the machine is broken, the machine is too close to the sedimentation tank and there is no protective measure. The potato slag in the machine splashes out and falls into the separated sedimentation tank to cause an increase in the amount of coarse fibers.

2 The separation screen has holes that have not been repaired in time to make the potato residue leak.

3 Containers or utensils used to contact starch milk are not cleaned, with potato dregs and sediment, contaminating starch.

4 When washing starch, the yellow powder and sediment layer are not cleaned seriously.

5 When the drying field is unclean or the wind is blowing, no dust-proof measures are taken to make the starch contaminate again. In addition, the use of unclean water in the production process will cause excessive impurities in starch and starch products.

Therefore, in production, according to the cause of excessive impurities, the corresponding control measures should be taken to ensure that the starch produced is white and pure.

Goodway provides high quality

cassava starch processing equipment, sweet

potato starch processing equipment, and

potato starch processing equipment. Welcome to inquire!

EN

EN

fr

fr  es

es  it

it  pt

pt