With the rapid development of industrialization, people's nostalgia for handcrafts is lingering, but the quality of handcrafted cassava starch must be better than that of whole-machine cassava starch?

We can analyze it from four aspects: color, taste, water content, health, and safety.

1. The Taste

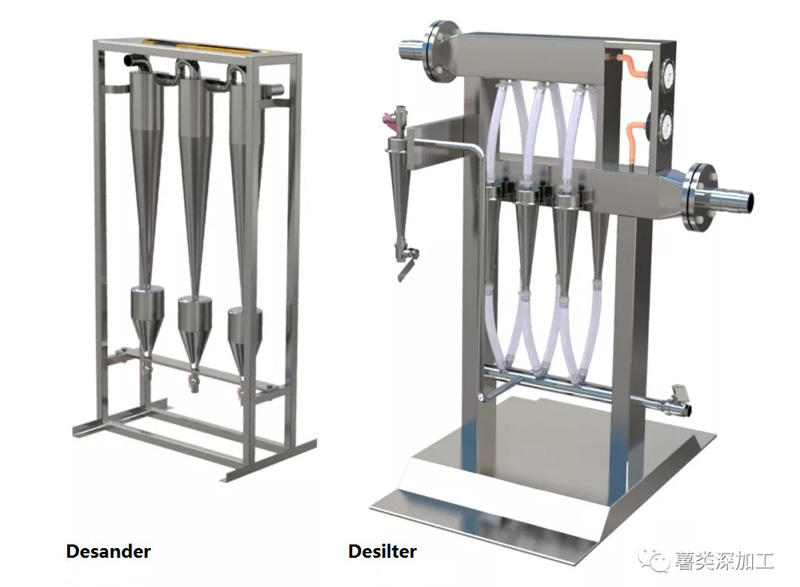

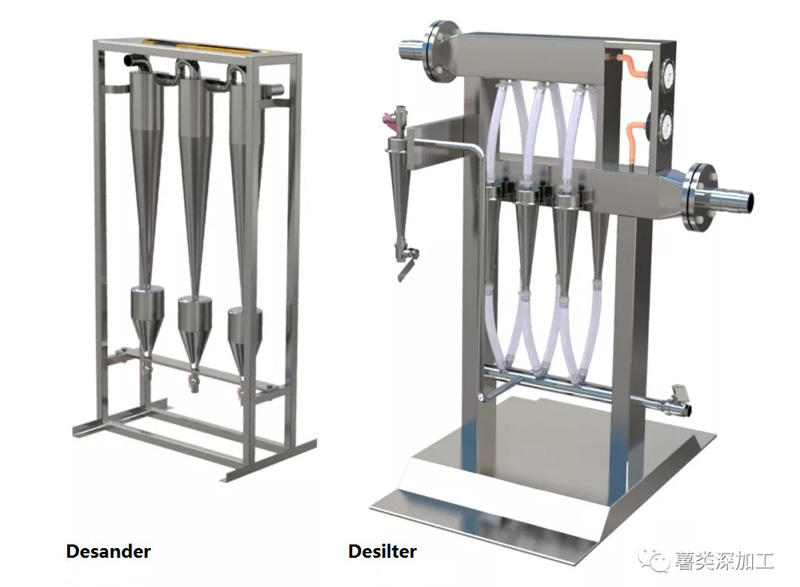

Impurity content is an important factor affecting the taste. The whole mechanism starch is processed by an industrial production line, which is equipped with professional cassava starch processing equipment. Cassava starch production line adopts professional cleaning, filtering, desilting, and sand removal devices, which can fully remove all kinds of impurities in starch. At the same time, follow-up dehydration and drying and automatic packaging equipment can also effectively avoid secondary contamination of starch.

Most hand-made products can only remove large particles of impurities, and the subsequent drying packaging is also prone to secondary pollution, increasing the content of impurities.

Obviously, in the treatment of impurities, the hand-made method is far inferior to the whole mechanism starch, and the taste is naturally not as delicate as the whole mechanism starch.

2. Color and Luster

When starch is manually produced, the continuity of the production process can not be guaranteed, especially in the crushing and separation process, the material will oxidize and brown, making the color of starch darker, and the production phase is not good.

In the industrial production of starch, the continuity of production can be realized. Especially in the crushing and separation process, the use of curved-net extrusion pulverizer or overflow washing potato pulverizer can integrate crushing and separation, avoid oxidative browning in the process of starch extraction, and produce starch with white and bright color.

3. Water Content

Cassava starch is difficult to store if its moisture content is large. The drying effect of the whole mechanism starch can reach the high-grade product with the water content of about 12%. The starch is dry in powder state and has less water content. Some of the hand-made starches are small fragments with the water content of 15%-20%. The water content of the starch is large and it is difficult to store.

4. Health and Safety

Hand-made starch is often lack of safety testing, production process and transportation links are not effectively guaranteed, its food safety and health status may not be comparable to the modern industrial processing of full-mechanism starch.

EN

EN

fr

fr  es

es  it

it  pt

pt