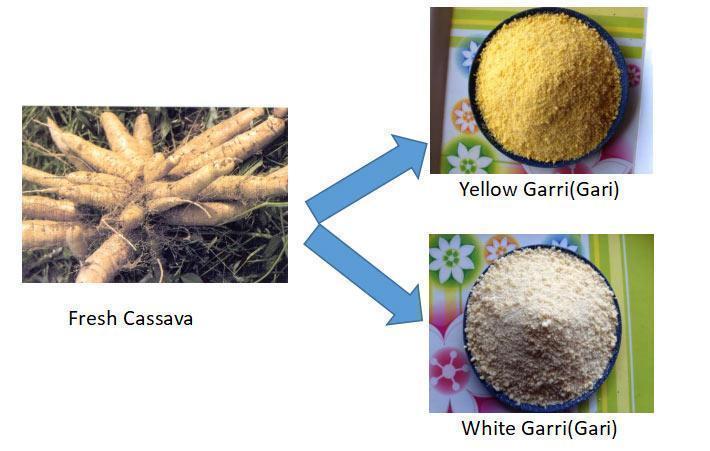

Cassava Garri(Gari) Process Description and Flowchart:

Garri is a fermented and gelatinized dry coarse flour, very popular in West Africa and a staple food in Nigeria, Ghana, Benin, and Togo. Its ability to store well and its acceptance as a "convenience food" is responsible for its increasing popularity in the urban areas of West and Central Africa. It is often consumed as the main meal in the

form of a dough or a thin porridge. Both are prepared in the household by mixing dry Garri with hot or cold water and cooking and are served with soup or stew. Garri is also eaten as a snack when mixed in cold water with sugar, and sometimes milk. It swells three to four times its volume when mixed with cold water.

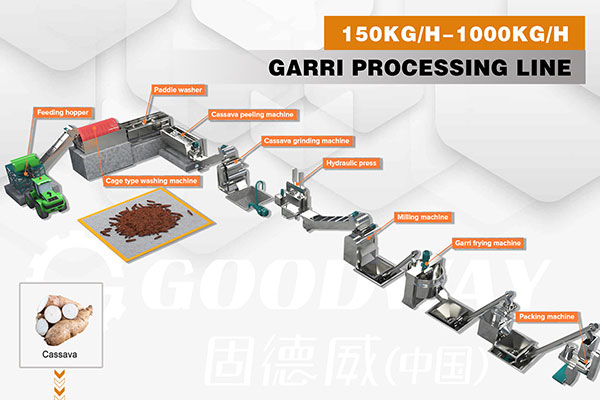

Goodway delivers the whole range of equipment for Garri processing industry from Garri processing machinery to complete the Garri processing production line. Multiple distinct operations are required in Garri processing: washing, peeling, grating, de-watering, breaking & sifting, Garri roasting, milling, and packaging.

We provide below a brief description of the main steps of the

Garri(gari) production process.

Cassava Gari Production Process Using Gari Making Machines

Find the Right Garri Processing Line for Your Scale

Choosing the correct equipment setup is crucial for your investment and profitability. Below is a breakdown of our most common garri processing machine configurations to match different production goals and budgets.

|

Scale & Daily Capacity

|

Key Equipment Included

|

Key Features

|

Ideal For

|

|

Small-Scale / Startup(100 - 500 kg)

|

• Cassava Grater

|

• Low initial investment

|

Entrepreneurs, family businesses, and community cooperatives starting garri making machine production.

|

|

• Hydraulic Press (Garri Presser)

|

• Semi-automatic, easy to operate

|

|

• Manual or Gas Fryer

|

• Flexible layout, minimal space needed

|

|

• Sieving Machine (Garri Sieving Machine)

|

|

Medium-Scale / Commercial (1 - 5 tons)

|

• Washing & Peeling Machine

|

• Optimal balance of automation and cost

|

Growing businesses and established factories looking for a reliable commercial garri processing machine line.

|

|

• Grater

|

• Higher efficiency and consistent output

|

|

• Hydraulic Press

|

• Excellent return on investment (ROI)

|

|

• Sieving Machine

|

|

• Automatic Garri Fryer

|

|

• Milling & Packaging Units

|

|

Large-Scale / Full Plant(10+ tons)

|

• Complete automated line with conveyors

|

• Maximum output with minimal labor

|

Industrial garri processing equipment plants and large agro-processors supplying regional or export markets.

|

|

• Continuous dewatering system

|

• Superior product consistency and hygiene

|

|

• Large-capacity automatic fryer

|

• Designed for high-volume, continuous operation

|

|

• Precision milling & automatic packaging machine

|

Note on Pricing: The cost of garri processing machines varies significantly based on capacity, automation level, and specific configuration. Contact us with your production target for a detailed and accurate quotation.

EN

EN

fr

fr  es

es  it

it  pt

pt